Flow meters

About Liquid Controls flow-meters generally

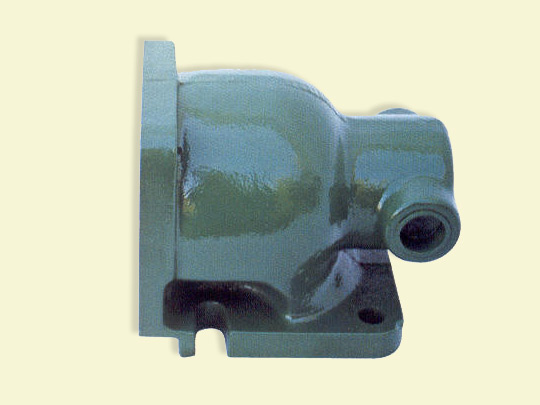

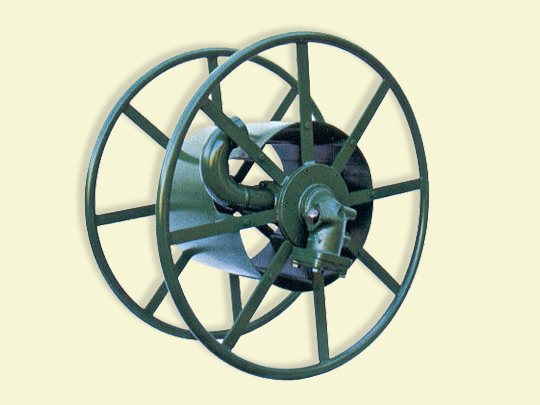

The Liquid Controls Meter consists of a housing in which three rotors turn in synchronized relationship within three cylindrical bores with no metal-to-metal contact within the meter element. Each rotor is supported on either end by a bearing plate through which the rotor shafts protrude.

The bladed displacement rotors alternately move through the two half-cylinder bores of the meter element, while the single blocking rotor rotates within its bore in such a way as to produce a continuous capillary seal between the unmetered, upstream product and the metered, downstream product.

At one end of each rotor shaft is a timing gear. The blocking rotor gear, having twice the number of teeth of each of the displacement rotor gears, rotates at halfthe RPM of the displacement rotors.

Throughout the meter element the mating surfaces are either flat surfaces or cylindrical faces and sections that are most accurately machined. No oscillating or reciprocating motion withinthe device permits extremely close and consistent tolerances within the Liquid Controls meter.

As a result the Liquid Controls meter provides unsurpassed accuracy (0,05%), long operating life and exceptional dependability.

The flow-meters produced for wide range of type of liquids, of course the sealings depend on the type of liquids.

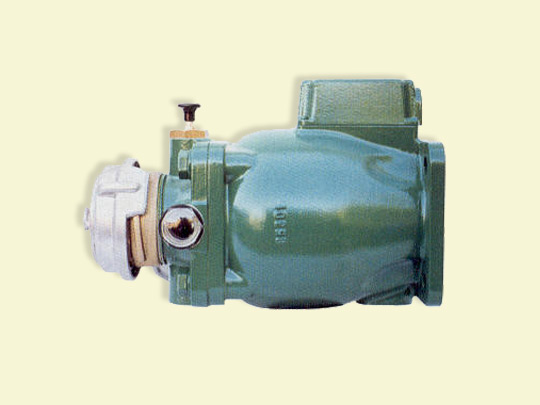

For the different flow-rates we can offer different type of flow-meters, as the follows:

|

Liquid Controls M5 Min. flow-rate: 22 liter/min |

|

|

Liquid Controls M7 Min. flow-rate: 38 liter/min |

|

|

Liquid Controls M15 Min. flow-rate: 76 liter/min |

|

|

Liquid Controls M30 Min. flow-rate: 135 liter/min |

|

|

Liquid Controls M50 Max. flow-rate: 1000 liter/min or 1300 liter/min |

|

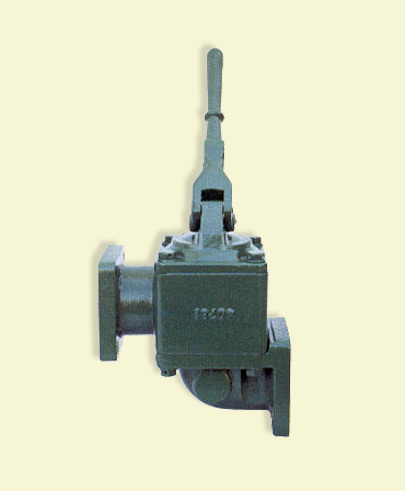

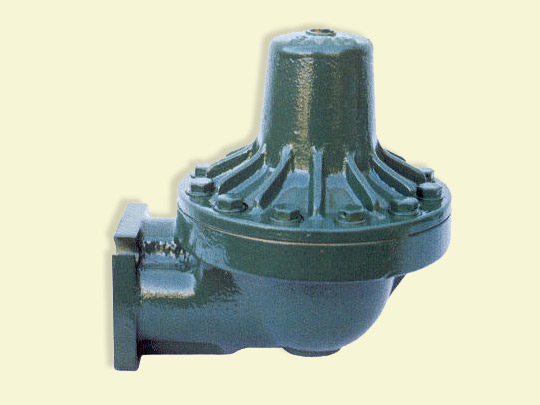

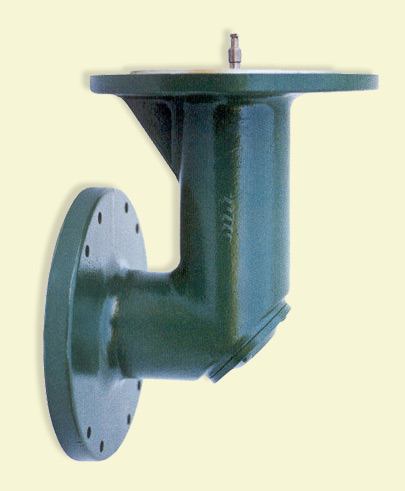

Hydraulic Pilot Valve (4" HPV)

- Two-staged shut-off valve, flow-rate control in conjunction with any electronic register with digital flow control.

- Liquid temp range: -20°C...+80°C

- Ambient temp range: -20°C...+80°C

- Max. counter pressure: 1,5 bar

- Max. working pressure: 10 bar for the aluminium type

16 bar for the carbon steel type - Minimum operating pressure: 0,09 bar

- Flanges: 4"

- Electro hydraulic Command: 220V 50/60 Hz or 24VDC or as requested

- Standard magnetic head: IP65 Explosion proof EExd IIBT6,

Power consumprion 20 W

TE500 single or dual electronic register

Single - The register can be used with one flow-meter and can be either placed on top of the meter or remotely mounted.

Double - The register has a dual display, works with two flow meters simultaneously, and is remotely mounted.

Main features:

- Totalizer display, 9 digit resettable counter showing volume delivered at ambient temperature, 9 digit resettable counter showing temperature compensated volume, 8 digit non-resettable counter showing volume delivered at ambient temperature, 8 digit non-resettable counter showing temperature compensated volume, flow rate indication, product temperature indication.

- Temperature compensation, accepts inputs from Pt100 Class A temperature probe.

- Reporting function, enable daily meter througput and summary of transactions to be displayed or printed. Large, back-lighted LCD dot matrix display guides the operator during loading.

- Easy programming, step by step menu driven configuration of parameters and controller functions.

- Linearisation, to compensate for the inherent error curve of the associated flow-meter.

- Memory function, all transactions are stored with the option to display or print data chronologically, or sorted by date.

- Automatic error correction re-calibration simplified by automatically calculating the static error of the associated flow-meter.

- Digital control: capability to drive an elctromechanical digital valve for flow-meter.

- Pulse transmitter, may be internal or remotely mounted,

- Serial communication, uses three independent EIA standard serial communication (RS232C, RS485, RS422).

- Self Diagnostic procedure, automatically checks essential components at each power-on.

- Explosion-proof enclosure, Eex-d IIB T6 certified in accordance with CENELEC Standards.

- Working temperature: -20°C...+55°C

- Weather-proof enclosure to IP65

- Metrological characteristics complying with OIML R 117 International Recommendations.